-webp.webp)

Application Industries

Application Scenarios

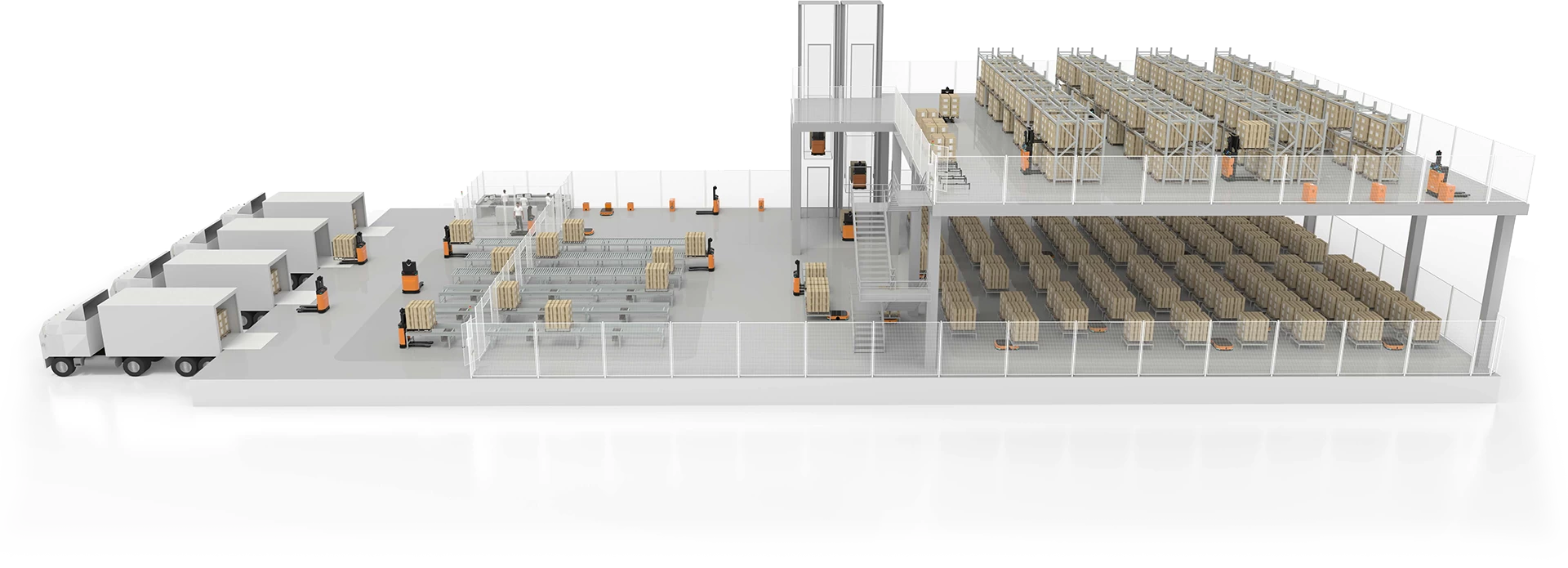

Inbound and Outbound Logistics

The implementation of Automated Mobile Robots (AMRs) has brought a transformative edge to inbound and outbound operations. Inbound logistics benefit from AMRs' autonomous navigation and inventory tracking capabilities, efficiently transporting incoming goods to assigned storage spaces while reducing errors. AMRs’ adeptness in locating, retrieving, and transporting incoming shipments to predefined storage locations has elevated the speed and precision of this process. Similarly, in outbound operations, AMRs excel in retrieving items from storage, optimizing picking routes, and expediting order fulfillment, resulting in heightened efficiency and accuracy. The integration of AMRs not only streamlines warehouse processes but also fosters a dynamic and productive synergy between technology and human involvement.

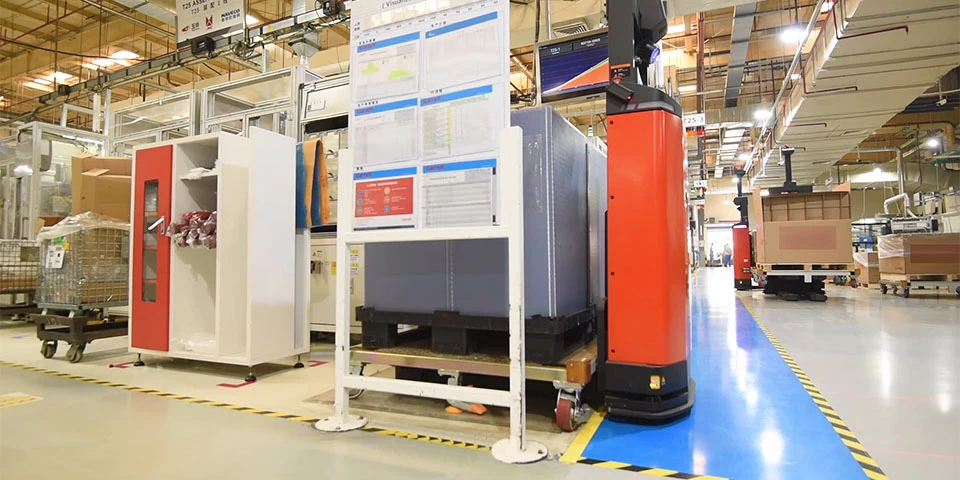

Production Flow

Our AMR systems are the key to unlocking your factory's full potential. These robots can help you connect the workflows and automate your production lines. They are safe, flexible, and adaptable, giving you the power to boost your productivity 4X. With our AMR systems, you can automate repetitive and dangerous tasks, improve efficiency and throughput, increase flexibility and agility, and improve safety.

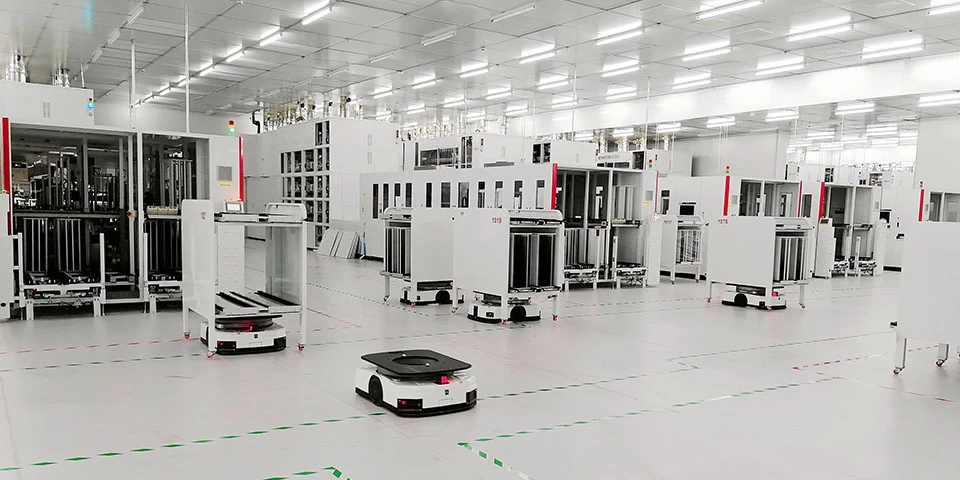

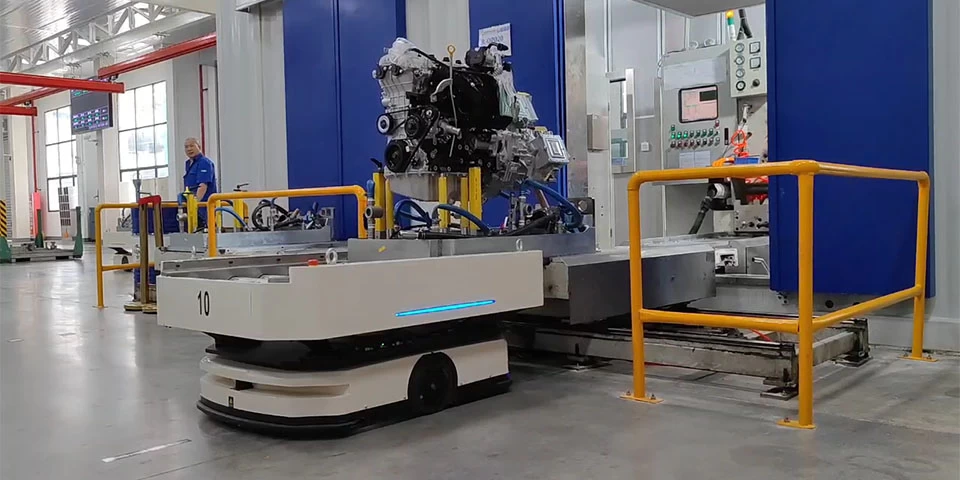

Material Handling

Streamline Raw, WIP, and Finished Goods Movement with AMRs!

Embrace the power of Just-in-time manufacturing procedures, seamless line feeding, and efficient handling of finished products as you transition to the era of Logistics 4.0. Elevate your competitive edge and operational agility effortlessly with our comprehensive array of solutions designed for diverse load types and workflows.

Imagine robots seamlessly transporting bins, carts, and pallets of goods to your production line, all while your workforce remains stationed and your facility unchanged. Our AMR system can be integrated with customers’ systems such as MES and realized the unmanned transportation of materials directly to/from storage. They even return empty carts for restocking.

Effortless Transportation and Transfer!

Utilization of robotic systems for transferring raw materials finished goods, and work-in- progress items. Ensure empty pallet supply and seamless connections with robots managing wrappers, labelers, palletizers, machines, and automated warehouses.

Kitting & Product line delivery

Curate sets of interrelated items, strategically supplied together to accelerate picking or manufacturing procedures.

.png)

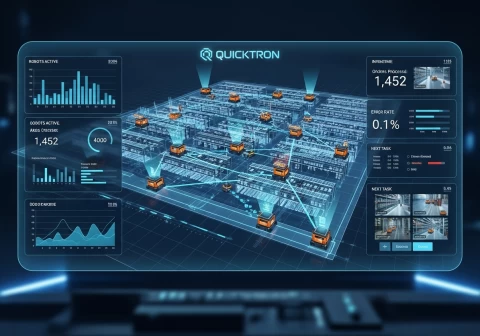

Software Platform

Quicktron's Logistics Execution System (LES) acts as the backbone of supply chain logistics, connecting high-level systems to on-ground operations. Using AI algorithms, LES manages material allocation, workflows, and transfer strategies, optimizing tasks like material handling, production flow, and inbound/outbound logistics for real-time accuracy. This enhances efficiency, reduces lead times, and overall supply chain performance. RCS follows instruction and schedules tasks, dispatches robots, and oversees maintenance. It uses diverse scheduling algorithms to allocate tasks optimally, enable multi-robot path planning, manage traffic, charge, ensure safety, and more. This versatility allows RCS to seamlessly coordinate various robot types in different scenarios, unlocking maximal efficiency through collaborative efforts.

-md.webp)