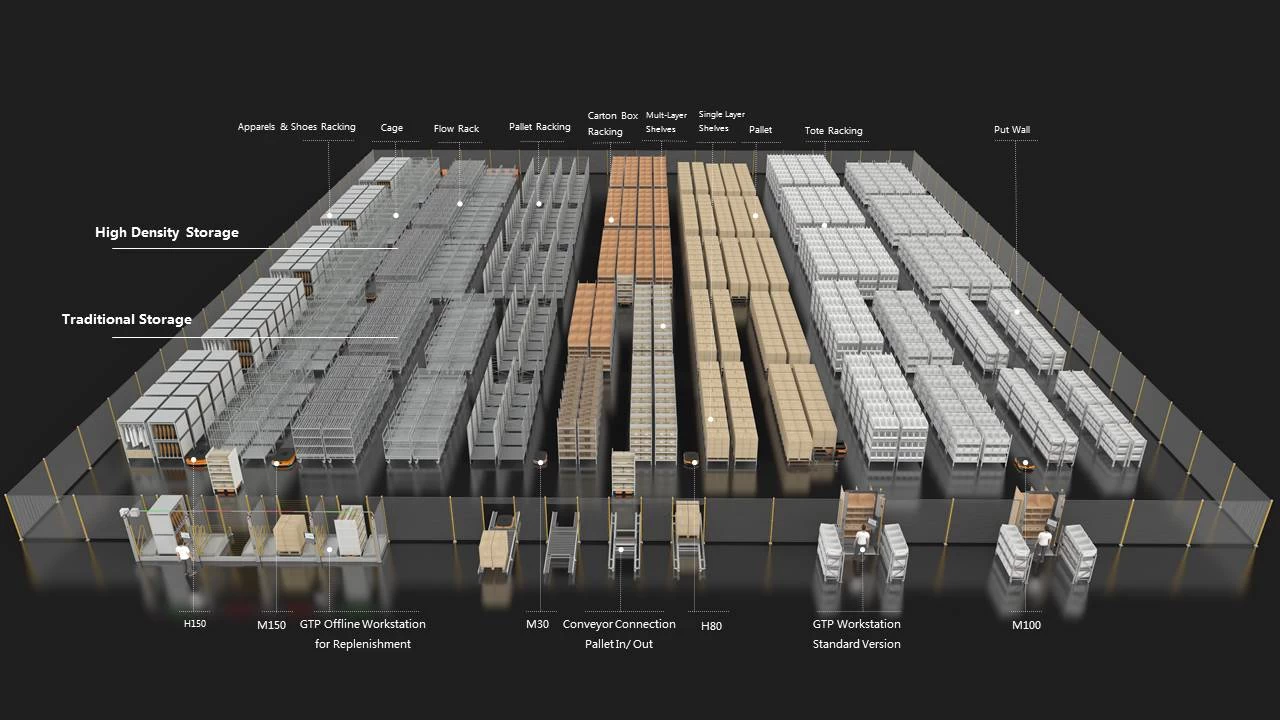

Shelf To Person Picking

Performance

Our GTP Picking Solutions have been meticulously designed to enhance order handling capabilities, ensuring higher order volumes are managed seamlessly while maintaining unmatched accuracy, making it an essential tool for modernizing logistics operations.

.png)

Software Platform

The Warehouse Control System (WCS) and Robot Control system (RCS) orchestrate the movement of autonomous robots, storage position allocation, optimizing paths, and ensuring precision, while the Warehouse Execution System (WES) intelligently assigns tasks, optimizing pick sequences for peak efficiency. This eliminates non-value-added activity in the warehouse. When all of the elements are combined, the efficiency of picking, replenishment, returns processing, and other processes is increased by 3-4 times.

Benefits

Eliminate Travel Time

With autonomous delivery of goods directly to operators stationed at their workstations, the need for travel within aisles is completely eliminated. This streamlined approach allows robots to handle the preliminary tasks, freeing operators to concentrate on the crucial final stages of picking and delivery.

AI-Powered Operations

Our AI-powered system combines real-time path planning, adaptive task allocation, and data analytics for efficient multi-robot coordination and dynamic storage. This optimizes operations for peak efficiency and responsiveness.

Scalable System

Designed for scalability, our goods-to- person systems effortlessly adjust to your company's expansion needs. They enable seamless increases in robot numbers for peak seasons and reductions during off-peak times, ensuring efficient resource utilization all year round.

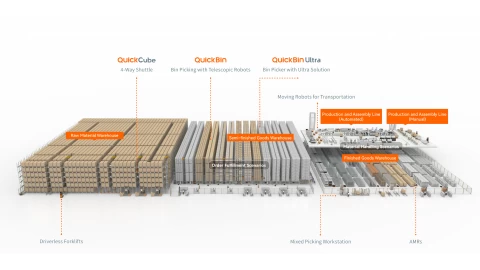

Application Scenarios

-webp.webp)

-webp.webp)

-webp.webp)

Application Industries

What are the customer challenges?

Value for the Customer

Performance Driven

Software and hardware use standardized modular design

Easy installation with minimal infrastructure changes

Flexible operation

Seamless connection with OMS/WMS/MES upper-level

systems shortens the implementation period

Efficiency

Precise operation with 99.99% Accuracy

Labor costs reduced by 60-80%

Advanced handling

Collision-free path planning, storage optimization, robot collaboration, and other algorithms ensure fast delivery of goods to the operator

Multiple orders can be fulfilled simultaneously.

Quick ROI

Average Payback in 1-3 years