Unlocking Operational Excellence Through Human-Robot Collaboration

Human-robot collaboration isn’t about replacing people. It’s about empowering teams with AMRs to boost efficiency, safety, and job satisfaction.

Here’s the thing: the future of warehousing isn’t robots taking jobs. It’s robots making human work better. Quicktron’s approach is to bring goods to people, handle the heavy lifting, and let your team do the work that actually requires judgment, dexterity, and care. What this really means is higher throughput, fewer injuries, and happier workers — all without ripping up your warehouse.

Real time Implementation Problems: In many distribution centers the bulk of a picker’s day is spent walking, not picking. That travel time adds up and drags productivity down. Quicktron’s site explains that Goods-to-Person approaches are designed specifically to solve that travel problem by delivering goods to workstations so operators can stay stationary and work faster.

What this looks like in practice: instead of pickers walking aisles, autonomous mobile robots (AMRs) bring shelves, bins, or pallets to a human at an ergonomic workstation. The human handles the fine-motor work and quality checks; the robots handle movement, lifting, and repetitive transport.

Quicktron’s toolbox for human + robot collaboration

Quicktron doesn’t bet on one robot type. They match solutions to the operational problem:

• QuickBin (Bin-to-Person) — a patented dual-robot solution combining tall C56 robots (store/retrieve at height) and fast M5 minis that deliver individual bins to pickers. It’s built for dense vertical storage and high SKU counts.

• Shelf-to-Person / G2P (Shelf/Pallet-to-Person) — AMRs pick and bring shelves or pallets to a human workstation for fast, accurate picking without the walking. This is a go-to when you want to maximize throughput while preserving human oversight.

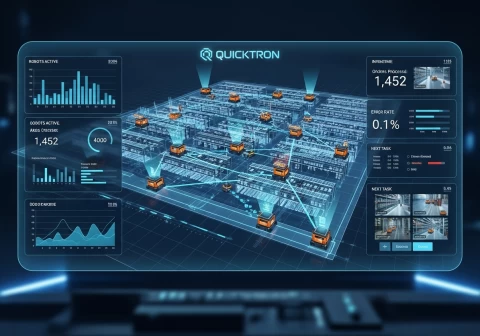

• Flexible AMR fleets — a range of AMRs for different tasks (material carriage, bin delivery, pallet handling) that can run together under the same software layer.What this really means is choice: pick the mix of bots that matches your SKU profile, ceiling height, and throughput target.

• Human friendly Software Interface:Robots are only useful when the software tells them where to go, what to pick, and how to avoid people and other machines. Quicktron’s software stack—WES (warehouse execution), RCS/WCS, and fleet control—integrates with your WMS and upstream systems so the whole operation runs like one orchestra. This software layer optimizes routing, slotting, and charging, and it helps AMRs coexist safely with people on the floor.

What this really means is fewer surprises during cutover: the WES coordinates orders, the fleet controller orchestrates robots, and your WMS remains the source of truth.

Real proof: Multiple Successful Case Studies Quicktron publishes several industry deployments showing how the human + robot model works in real operations:

• A large Radial deployment demonstrates how coordinated fleets and software can handle thousands of order lines per day while using hybrid human workstations to process complex items.

• QuickBin projects in markets like Japan and China show how maximizing vertical space and combining tall & mini robots can address labor shortages and limited footprint constraints. • Health-industry sites (e.g., Tianjin SLC) illustrate intelligent inbound/outbound flows where WMS → WES → robot orchestration improves storage accuracy and outbound speed while keeping human quality checks in the loop.Bottom line: these are real workflows where robots increase throughput and free people for higher-value tasks.

Benefits for people: safety, skills, and satisfaction

Here’s what warehouses actually see when they shift to human-robot collaboration:

• Less physical strain — robots move heavy cases and bins so people avoid repetitive lifting and long walks.• Fewer mistakes — robot delivery to workstations reduces mispicks and simplifies workstation training.• Opportunities to upskill — operators move into roles like quality control, exception handling, and station supervision, which are harder to automate and more meaningful.What this really means is you get a safer, more skilled workforce and lower turnover — the kind of operational stability that helps margins.

A More Productive and Engaging Future

Harnessing Quicktron Robotics' advanced AMRs and automation solutions will unlock new levels of operational excellence for your business. Our technology has demonstrated up to 60% cost savings and 99.99% accuracy in fulfillment processes, supported by over 30,000 deployed units worldwide.

As we continue to innovate, our commitment remains steadfast: to provide sustainable, high-efficiency, and human-friendly robotic solutions that transform warehousing into a highly productive, safe, and engaging domain.Ready to see what a human + robot warehouse looks like? Request a site assessment and Quicktron will map a pilot that keeps your people front and center.