Quicktron Robotics to Showcase Hybrid Intralogistics Automation Solutions at LogiMAT 2024

Quicktron Robotics, a global leader in intelligent intralogistics automation, is set to unveil its cutting-edge robotic solutions at LogiMAT 2024, the premier trade fair for intralogistics and supply chain management, taking place from March 19-21, 2024, at Messe Stuttgart, Germany.

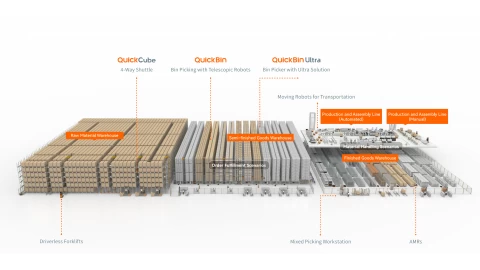

Visit Quicktron at Hall 6, Booth No. 6F75, to witness live demonstrations of our innovative lineup of mobile robots and automation systems designed to optimize intralogistics operations for businesses of all sizes. The company will demonstrate how its hybrid automation, which combines multiple automation systems into one, can help businesses achieve greater efficiency, productivity, and space savings.

What to expect?

Mobile Robots:

- C56 Tall Picking Robots: Towering up to 10 meters, these robots excel in storing, sorting, and picking totes in high-bay warehouses.

- M5 Mini Robots: Nimble and compact, perfect for swift deliveries of totes and small items to pickers at workstations.

- M100 Robots: Capable of handling up to 1500kg payloads, ideal for the movement of pallets, shelves, and heavy objects.

Warehouse Automation Solutions:

QuickBin (Bin-to-Person System):

QuickBin is a dual-robot (C56+M5) picking system that optimizes warehouse operations, specially designed for fast processing of small-size inventory. It maximizes vertical space utilization and accelerates order fulfillment. Tall robots (C56) store bins vertically up to 10 m (32.8ft) high, maximizing space, while mini robots (M5) swiftly deliver bins to pickers at workstations, minimizing errors, and boosting throughput. With QuickBin you achieve a pick rate of 400+ order lines per hour per station.

Hybrid Goods-to-Person (G2P) Systems:

Hybrid G2P system is designed to handle diverse inventory sizes and shapes. It's a flexible merger of Shelf-to-Person and QuickBin systems and works with three types of adaptable AMRs and innovative software. Tall C56 robots navigate aisles and store totes in vertical racks, Mini M5 delivers totes to pickers at workstations and M100 handles the pallets and shelves. With flexible mixed storage, you can store diverse items—totes, shelves, and pallets—in one location for maximized space utilization, and better inventory control. One of the stand-out features is hybrid workstations, a one-point handling of all item sizes. Pickers access totes, shelves, and pallets seamlessly at centralized picking stations, boosting throughput.

Key benefits: Boost operational efficiency 3-4 times, save 75% of warehousing space, reach 32.8 ft vertical height, reduce labor costs by up to 60% handle all items in one place, and achieve a 4x increase in order fulfillment speed.

Factory Automation Solutions:

Our hybrid Point-to-Point material handling solutions seamlessly integrate various robot types into manufacturing flows, streamlining internal logistics effortlessly. With a 99.99% accuracy in movement, they ensure both safety and productivity in manufacturing workflows.

Key Benefits: Adapt to changing needs, decrease cycle time, enhance safety, reduce labor costs by up to 60%, and optimize resource utilization.

Expressing his enthusiasm for the upcoming event, Yang Wei, CEO of Quicktron Robotics, highlights the adaptability of their Hybrid systems. According to Yang “Hybrid systems offer space-saving mixed storage and convenient, one-stop picking for all item sizes," states Yang Wei, CEO of Quicktron Robotics. He further affirms, "With a technical facility in Germany and a deep understanding of European needs, we are confident that our intelligent automation solutions will resonate with European businesses seeking to optimize operations and gain a competitive edge.

Yang Wei, CEO of Quicktron Robotics

Whether you manage a warehouse, factory, or fulfillment center, Quicktron Robotics has the flexible solutions you need to gain a competitive edge. Join us at LogiMAT 2024, Booth No. 6F75 to Boost Efficiency, Slash Costs, and Drive ROI.

To book a meeting with our expert in advance, contact us at info@quicktron.com or register here

About Quicktron Robotics:

Quicktron Robotics is the pioneer of hybrid intelligent intralogistics automation using AMRs and is committed to accelerating the future of intralogistics. Our intelligent robotic systems adapt to every warehouse or manufacturing layout, moving goods safely and efficiently while freeing your team to focus on what matters most. With 28,000+ robots operating globally, Quicktron is the trusted efficiency partner for businesses of all sizes.

Contact:

Quicktron Robotics

Email: info@quicktron.com

Website: www.quicktron.com

Arslan crafts compelling content, executes social media campaigns, and masters online ads, webinars, podcasts, and copywriting. He builds strong relationships with clients, empowering them with support and resources to achieve their sales goals. Leveraging data insights, he refines strategies and collaborates seamlessly to stay ahead of the digital curve.