How Warehouse Robotics is Transforming Apparel Logistics?

The fashion industry is a whirlwind of trends, seasons, and ever-changing demands. But behind the glitz and glamour lies the complex world of logistics, where warehouses hum with the activity of getting clothes from runway to retail rack. This is where Quicktron Robotics steps in, revolutionizing the game with warehouse robots specifically designed for the unique needs of apparel.

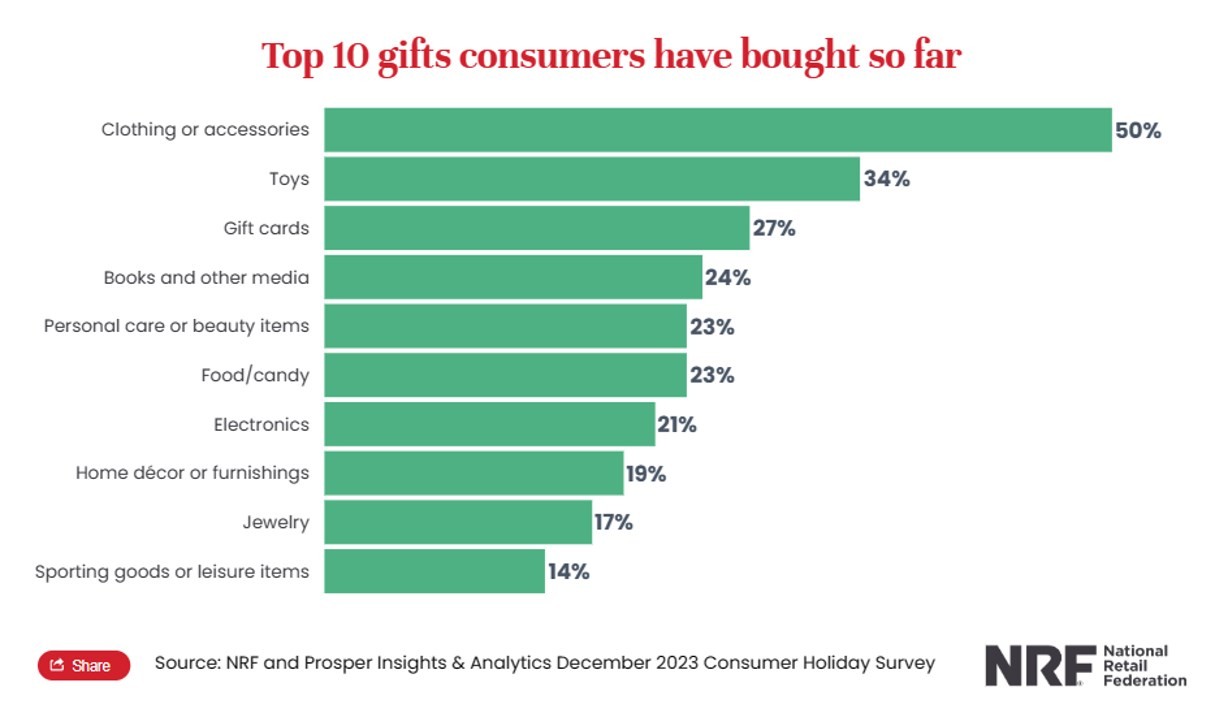

Apparel shopping dominated holiday sales in 2023, with 50% of shoppers choosing clothing as gifts, as reported by NRF. The rise in e-commerce is putting constant pressure on apparel retailers with distinctive challenges in their supply chain such as the need for quick order fulfillment, accurate inventory management, and the handling of a vast array of product sizes. Traditional warehousing methods often struggle to keep up with the dynamic nature of this industry, leading to delays, errors, and increased operational costs. Warehouse robotics can help apparel brands address a wide range of operational needs and get ahead of the competition.

Key Features of Quicktron’s Warehouse Robotics for Apparel:

Smart Inventory Management:

Traditional Inventory management struggles with modern demands, leading to delays, errors, and increased costs. Quicktron offers a strategic approach to keep everything organized.

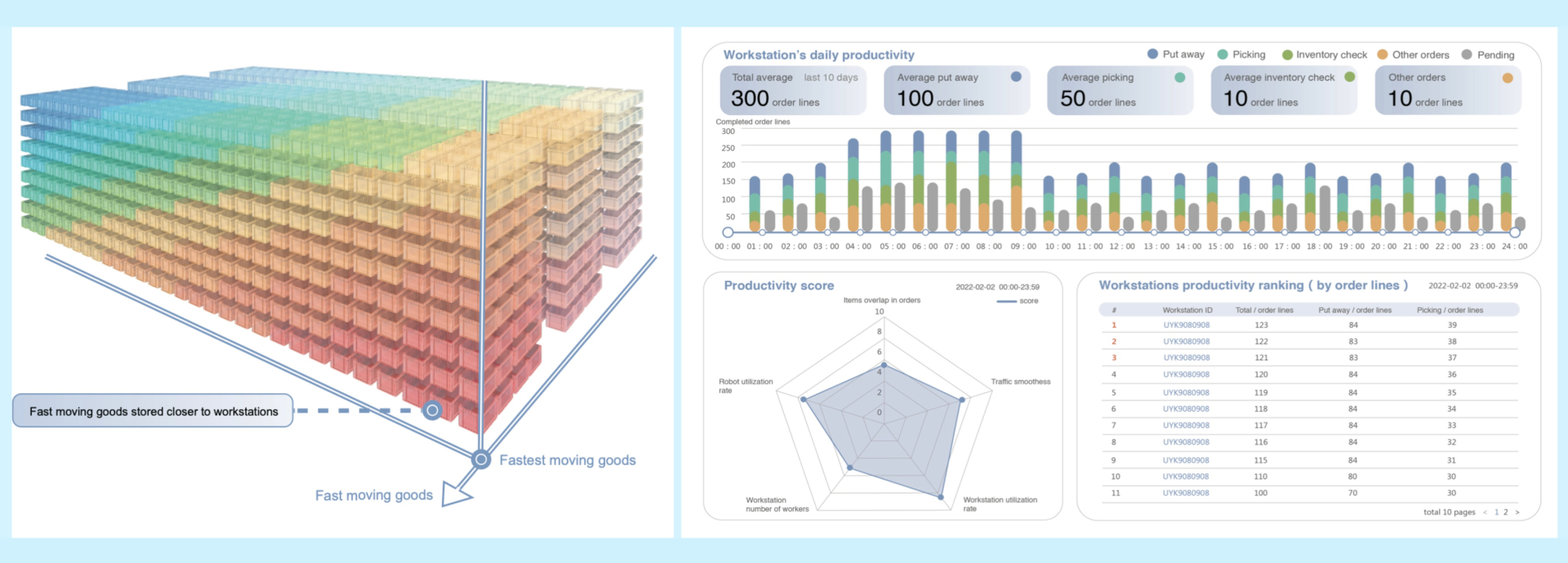

- AI-powered sorting algorithms: Equipped with AI our robotic system categorizes and organizes items based on size, style, demands, and other parameters for accurate picking.

- Real-time data analysis: Based on order history system prioritizes hot-selling items and stores them closer to workstations for faster fulfillment.

- Integrated analytics platform: Gain valuable insights into robot performance, workflows, and areas for improvement...

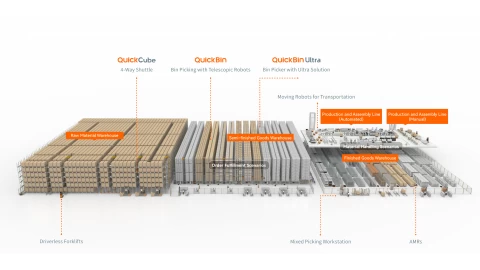

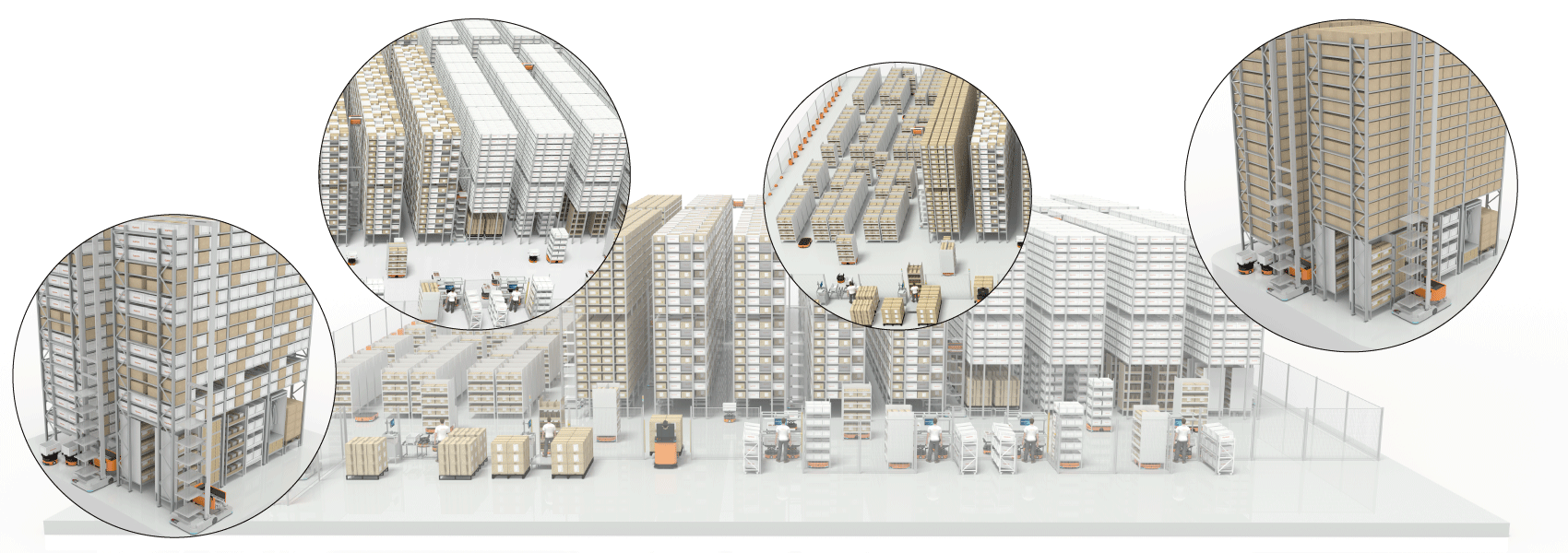

Hybrid Storage Layouts:

With our adaptable storage solutions, apparel warehouses can centrally store and access different types of inventories – totes, pallets, and shelves – all in the same area. This saves space, improves picking times, and helps them keep better track of their stock.

- Maximize space utilization: Store different product sizes in the same area using a flexible mix of multiple configurations, increasing storage capacity by 75%.

- Versatility for diverse items: Handle delicate fabrics, bulkier garments, and everything in between all at one location strategically placed and organized.

Optimized Order Fulfillment:

Win in today's fast-paced apparel market with robotic fulfillment. Our solution uses multi-type adaptable robots that navigate aisles and deliver goods to pickers 4x faster with 99.99% accuracy, exceeding customer expectations.

Hybrid workstations for maximum throughput: Robots deliver different sizes of inventory to these centralized workstations, increasing throughput as well as maximum convenience for pickers to pick all sized items in one place.

Today's shoppers want it fast: 40% crave their orders within 24 hours, 25% of shoppers cancel slow orders. At Li Fung (Now Maersk), an apparel fashion brand, our 76-robot army makes it happen, fulfilling orders 4x faster than before and achieving their 24-hour delivery goals.

Data-Driven Insights:

Gain valuable insights into your warehouse operations with Quicktron's integrated analytics platform. Track robot performance, optimize workflows, and identify areas for improvement, all based on real-time data collected by the robots themselves.

Eliminate stockouts and overstock: Gain real-time visibility into inventory levels for better restocking and optimization.

Scalability and Flexibility:

Quicktron Robotics understands that the needs of apparel businesses can change rapidly. Our solutions are designed to be flexible and scalable. Whether it’s a peak season, capitalizing on viral trends without losing profit margins, or an off-season, give your warehouse operators peace of mind knowing they can accommodate a sudden peak with a reactive and reliable order-picking system that can be scaled within minutes by adding more robots.

- Expand automation as your business grows: Quicktron's solutions are modular and adaptable.

- Seamless integration: Works with existing warehouse management systems for a smooth transition.

Conclusion:

Quicktron Robotics is at the forefront of revolutionizing apparel warehousing through its tailored robotics solutions. By addressing the unique challenges of the industry and offering a suite of smart, flexible, and efficient automation tools, Quicktron empowers apparel businesses to stay ahead in a competitive market. As the demand for streamlined supply chains continues to rise, Quicktron Robotics stands as a beacon of innovation, shaping the future of apparel warehousing.

Arslan crafts compelling content, executes social media campaigns, and masters online ads, webinars, podcasts, and copywriting. He builds strong relationships with clients, empowering them with support and resources to achieve their sales goals. Leveraging data insights, he refines strategies and collaborates seamlessly to stay ahead of the digital curve.